Installation Guide for FreeRide Wakeboard Tower:

All Aerial Wakeboard Towers have been carefully designed to allow anyone with average do-it-yourself skills and access to a set of common tools to complete the installation with no problem in just a few hours. There a just a few important but simple technical tips you'll want to use. Well over 90% of our customers have installed the towers and accessories themselves and have reported back that it all went very well.

Properly installed, the FreeRide tower is one of the strongest aftermarket wakeboard towers on the market. It can absolutely go toe-to-toe with a factor made OEM tower.

Remember, if you get stuck, you can call our support team at (843) 948-6915 Monday through Friday 9am to 5pm EST. We'll be happy to walk you though. Remember to scroll all the way to the bottom of the page for a list of extra tips and reminders before getting started. You can do this!

Your FreeRide Wakeboarding Tower is designed for years of enjoyment. Please read through these instructions before beginning installation.

Important Tower information

- The FreeRide tower fits boat with beam width of 75-100 inches. This measurement is taken from the mounting points, so the side to side must be greater than 75 inches in the front and back.

- Do not fold the tower without having the top section bolted

- Do not fold the tower by your self

- Do not assemble tower on the ground and then try to put in on the boat

- Do not tow tubes or other types of inflatable towables!It makes your warranty null and void. Every tower manufacturer and boat manufacturer with an OEM tower has a warning not to do this. Inflatables and towables like these have a completely different hydrodynamic and friction profile compared to slick wakeboards and skis. The increased stress transfers through the tower to the mounting feet to a boat's fiberglass hull. Avoid damaging your boat and tower; avoid hurting or injuring your boat's occupants- just use your boat's ski tower ring.

- Do not use impact drivers on any hardware - this will over-torque them and possible cause damage

- Torque set screws to 35ft-lbs

- Torque shoulder bolts 50 ft-lbs

- Torque tower foot all thread to 65 ft-lbs

- All set screws should have red lock tite

- Check the top section for burr’s we are not liable for them

- You might notice your tower moving side to side when you tow your Boat, but, actually, the boat on the trailer is actually moving too.

- If your fiberglass is less than ¼ you will need to purchase a backing Plate kit

- Please leave foam wrap on until finished installing the tower

- If you have any question during the install please contact Aerial Wakeboarding

CLEANING

- Wash with soap and clean water

- Use clean, soft micro fiber cloths to avoid scratching

- Mothers Mag & Aluminum polish will restore to original finish

IMPORTANT WARNING

- BE CAREFUL when assembling this product! We CANNOT be liable for any burring or scratching that may occur when sliding sections in and out of each other. Before sliding on the top cross section tubes, check the inside of the tube opening. If you find a rough edge, we recommend filing and sanding them down smooth. Again, the point to to avoid scratching the nice polished finish of the tubes you're sliding them over.

- NEVER modify this product in any way

- NEVER climb, ride or stand on this product

- NEVER pull tubes or inflatables from the tower

- ALWAYS use caution with approaching bridges and overpasses

- ALWAYS inspect this product for loose bolts and damage before each use

- CONSULT user manual for proper installation, maintenance and usage

- AERIAL WAKEBOARDING is not liable for personal injury or property damage from the use of this product.

Determine placement of tower. This tower fits 75-100 inch wide hulls.

TUBE TRIMMING

Where a narrow fit is required the side section tubes may require trimming. Use a hacksaw to trim each tube and then deburr the edges with a file.

Tower can be mounted as a top or side mount-see hull mounting section

Detail of how base installation on hull

Tower dimensions.

Exploded view.

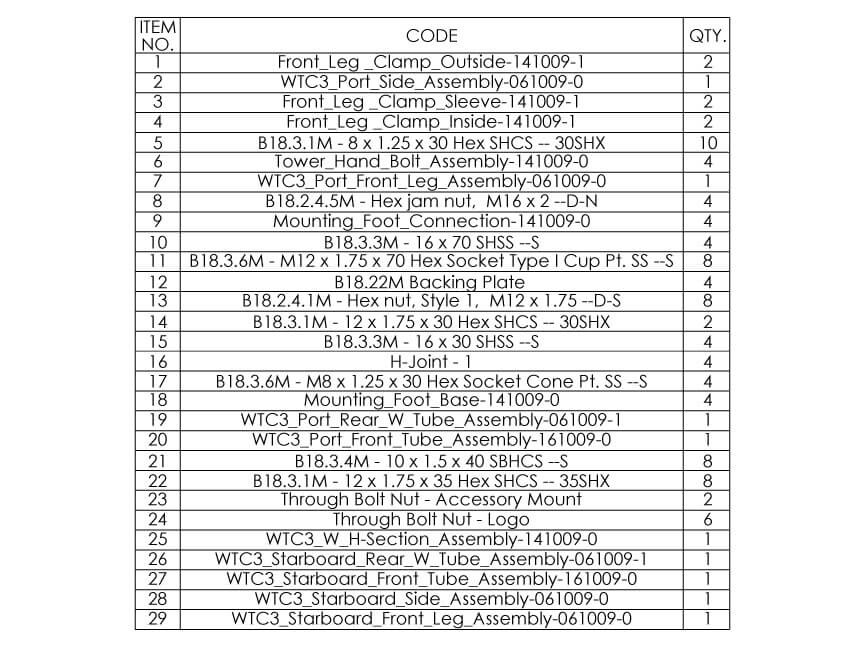

Parts List

Start by carefully opening the plastic bags and inspecting all items. It is best to do so on a moving blanket or a soft surface.

If you discover any defects (defined as marks more than 1 inch long), please contact Aerial Wakeboarding immediately BEFORE installation. Note that wakeboarding towers are handcrafted metal products. It is possible and acceptable for minor blemishes and marks to appear on the finish.

IMPORTANT: We recommend returning items to their plastic bags to protect them during installation.

Installation Checklist:

- Blue 3M tape

- Drill (capable of accepting bits up to 1/2 inch)

- File

- Drill bit set ranging from 1/4 - 5/8 inches

- Ratchet set

- A Permanent Marker

- A buddy to help out

Tape off all the areas that may potentially come into contact with the side rails

Arrange upper arms so you can identify items #20, 26, 19 and 27.

Upper Arm to side Rail

- Please see diagram above to determine the upper arms.

- They should bolt together very easily

- Leave them one turn from being tight

- This will help slide into the H-section #25

H-Section (#25)

- Be sure to check the H-section for any burr or defects prior to inserting the upper arms Aerial is not liable for burr’s

- The clear Milar should be wrapped around the tube before you insert it into the H-section, once your tower has been installed you will remove it. The Milar is there to help prevent any scratch’s from sliding the tubes in and out.

- You will just tuck the wire for the tower light into the tube for the time being.

- When you get to the wiring step you will remove one of the upper arm and run the wire through it.

Placement/Folding

- Tower folding is always a 2 person job

- Placement is key. Remember this tower folds forward.

- Start by loosing the quick knobs on the main clamp.

- Remove the shoulder bolt from the Heim joint and tower foot. Repeat for the other side. Swing the from supports into the boat, and the tighten down the quick knobs.

- It will now be free to fold forward/down. A boat fender or cushion works well for padding.

- Always tow with you tower in the UP position (do NOT fold and tow).

Tower Placement

- Once you have put your tower together, go a head lift the tower on the boat. (just the main frame)

- If you have an over head garage or tree you might be able to use it to take up the weight.

- This will help determine where the tower will fit on you boat. Remember to check the under side prior to drill for wires, also make sure you have access to that area.

- Once you have a general area for the rear tower feet, go a head and make some marks.

- You will need to measure to make sure that you have the tower feet in the same place side to side.

- As a note some times cleats are not in the same place on your boat.

Drilling for the Rear Feet

- Once you have marked your 4 holes, check the underside for wires.

- If necessary, you should move the wires out of the way while you drill. We recommend drilling a small pilot hole which will keep the 5/8” drill bit from walking (moving). A small rat tail file can be used to ease the edge and keep the gel coat from chipping. Be careful of wires!

Assemble feet.

Backing Plates

On the inside of your boat will be the backing plate, a nylock nut. If your fiberglass is less than 1/4” thick, we recommend reinforcing the areas where your tower will attach. Remove just enough blue tape for your tower feet to snugged up to your boat. Aerial sells a backing plate kit with instructions, it will add 20 minutes to the install and is cheap insurance.

Bolting the Feet to the Deck

- Use part number 11 with lock tite

- Make sure you have chamfered the edge before inserting the foot to the deck. ( if you do not, you will get gel coat cracking)

- There is a rubber washer that goes between the base and the deck

- Use the supplied the backing washer and nylock nuts

- Get them snug, you will tighten after the tower is complete

Connect Tower Feet to Main Frame

- Once both rear tower feet are secure go ahead and lift the main frame up.

- You will use the shoulder bolts part #10 3. We recommend that you insert the shoulder bolt from the inside of the boat.

- The frame should be able to move up and down at this point.

Forward Support

- 1Start by assembling parts- 7,8,9,10,15,16,17

- Snap #3 on to the main frame

- At our shop we have an over head lift, we used this to hold the tower in the “up position”

- Put #1 and #7 together with part #14

- It is easier to build the right & left together

- With you friends help take the assembled front support and clamp it around the tower with parts #4,& 6

- By “hanging” the tower you can step back and find the “look” of you tower. You might want to lower or raise it depending on your boat.

See illustration for side assembly.

Front Tower Foot

- This step will be the same as the rear Once you have marked your 4 holes, check the underside for wires.

- If necessary, you should move the wires out ofthe way while you drill. We recommend drilling a small pilot hole which will keep the 5/8” drill bit from walking (moving). A small rat tail file can be used to ease the edge and keep the gel coat from chipping. Be careful of wires!

Drilling the Front Support

- Once the tower is in the “air” you will need to mark the 2 holes that you will have to drill in the front support. Use a 9mm drill bit or a 23/64 drill bit.

- Use a sharpie to mark the holes on both sides.

- Disassemble the front support apart to drill the holes.

- Once drilled put the support back together and bolt it.

Drilling the Top Section

- Once the tower is “up” mark the hole and drill them with a 3/8 drill bit

- The FreeRide tower has parts # 24 which is the integrated nut.

- Part #23 is the integrated speaker clamp.

Wiring

- There are channels in the lap joints for wires

- These channels are designed for the speaker wires and navigation light wires to be ran through them

- Yes where the tube in the main frame steps down for the clamp it is hollow. At the very bottom of the tower about 2 inches up you will drill a hole for the wires to exit the tower

- There are couple ways of getting the wire through the tower:

First option is to use a wire fish, and fish the wires through.

Second is to use a vacuum and suck a light piece of string or rope through.

Then tape the wires to either the fish or the rope.

The Aerial wiring harness comes with a deck fitting for the wiring to pass through.

Tower Light

As of January 1st 2010 all towers must have a 360 navigation light at the tallest point, in this case we have integrated an USCG 2 mile certified light.

The wires for this light will be ran down through the tower and tied into 360 navigation your boat already has.

Important Tips and Considerations

The biggest tip we can give you is to "measure twice and cut once." There's no actual cutting involved, but you get the idea. Before you drill the first pilot hole into your boat's hull, be 100% positive it's the right spot and you've double checked with your tape measure. Second tip is to plan and execute the EXACT same steps for drilling and installing port and starboard. This is especially important for determining where you drill and mount the feet. Having offset mounting feet will result in a wakeboard tower that is off-center and askew. When determining the final drilling spots, use existing features or hardware on the boat to start your measurements(like the base of the windshield, rub rail line, etc.) then repeat on the opposite side(assuming they are located in the same spot). Third, open the box(es) your tower was shipped in and do an inventory to make sure no parts or hardware is missing. We take extra care to make sure everything is packed in, but it's a good idea just in case- that way if a part is missing of defective, you can contact us to send out a replacement before you begin. Put them all in a safe and uncluttered spot where they won't be lost until you are ready to begin.

Here are some other things to consider for your wakeboard tower installation:

- Have All Tools and Material at the Ready

Remember to create a list from the "tools needed" section and have them all ready before you start. If you want to chamfer after your drilling, add that bit to the list. Have a set of socket wrenches with the correctly sized bits. Only have old worn out drill bits? Add new ones to the list. Did you do a full recharge on your power drill? Have enough painter's tape? Maybe have some 3M 5200 Marine Adhesive ready just in case. Have a tube of Loctite? On the day of your install, it really helps to layout all the parts and hardware on a an old blanket that has some thickness for padding. This will help you visualize what needs to be done, keep you organized and speed up the process. - Have Someone There to Help You

We highly recommend having a family member or buddy out helping you during the process. Not only will it speed up the install, but also the last thing you want to do is accidently drop a tower section and potentially wreck your fiberglass, your beautiful new tower, or heaven forbid, your noggin. - Reinforcing the Hull

We usually recommend a backing plate kit to all our customers to provide extra support and strength to the boat's hull just under each tower mounting foot. Depending on the thickness and amount of reinforcing your boat manufacturer originally provided, it might not be necessary. The plates of marine grade plywood will help give a more even distribution of the pressure exerted to the mounting feet from the tower. Over time, an improperly reinforced foot might result in spider cracking or fiberglass damage.The pendulum forces created by a wakeboarder combined with the drag of cutting in on the board transfers a lot of energy to the tower and the boat. - Drilling Into Your Boat's Hull

Probably the step our customers get most nervous about is taking a drill bit to your baby's fiberglass. It seems unnatural, right? Here are a few simple pointers to follow- if that's not enough, remember there are many online articles and YouTube videos. First, make sure you are using new, sharp drill bits. Once you know the general location your mounting feet are going, add a wide patch of painter's tape before doing your final measurements. That way, when you go to mark the spot with with your Sharpie pen, it will be already taped and then visible. Before you start drilling, make sure you have about a 6 inch diameter of tape around the drill spot to protect your gel coat from accidental scratching from the metal drill and to help keep the fiberglass from splintering.

There are several ways of performing the drill. One way is to run a pilot hole through with a smaller bore bit, followed with the final bit size. To protect the gel coat, run the drill in reverse at medium speed with medium pressure. Remove the tape after then chamfer the edge of the hole to help prevent spider cracking. The best way to do this is to use a chamfer bit using just a little pressure for a few seconds. You can also use a rat tail file or other conical shaped saning bit. Either way, you want to create a 45 degree angle from the get coal to the fiberglass. Why is this an important step? When it comes time to installing the hardware, you do not want a hard edge on the hole- when the hardware tightens down, the pressure on that little extra gel coat material pushed out creating fine spider cracks. Similar to your car's windshield, a small crack will keep spreading over time. - Wakeboard Tower Maintenance

It's a good idea to regularly break out the tool set and retorque the tower and make sure everything is tight and secure. As previously mentioned, wakeboarders transfer a lot of energy and movement to the tower which can loosen fittings over time. This is true for any wakeboard tower even a factory installed one. Quick debunking: You may have seen videos online of wakeboard tower "shake tests" where the tower looks very wobbley- it's the result of improper maintenance or an improper installation to begin with. For some of the videos, we would even go as far as stating that some were filmed and anonymously posted by a specific manufacturer trying to hurt the reputation of others. They all show a lot of excessive movement at the heim joint, leg joints, top section that can only result from purposely loosening bolts. - Accessories

Planning on installing wakeboard tower speakers, light bars or other wired tower accessories? Make sure you have all the wiring you need. For the cleanest looking installation, you will want to run all the wires through the inside of the tower. Planning and executing this step now while the tower is unassailable is ideal. To keep water out of the tower's tubing, many customers use rubber grommets available at any home improvement store. For more great tips on how to wire your tower, feel free to give us a call. - Factory Folding Biminis

If you are hoping to use your existing folding bimini with your tower, be aware that depending on the tower you choose, where the bimini is installed, the bimini dimensions, and where and how you install the tower, it might not work. Most customer can use their old bimini no problem. Many, opt to upgrade to an Aerial Tower Bimini. If you absolutely want to keep your folding bimini, we can't give you a guarantee but you may have options that could give you enough extra width or height to allow your bimini to clear the tower frame. Since our towers have an adjustable width and the mounting feet swivel, your bimini might still work. It just requires a little more planning and measuring. - Aerial Authorized Installers

For those customers that are simply short on free time or not fully confidant in their own handy work, another option is to reach out to your local boat shop and get a quote on a typical 3-4 hour tower installation. We have a list of Aerial Authorized Installers to help you get started.

Have More Questions About the Installation?

Call (843) 948-6915 MONDAY - FRIDAY / 9 - 5 EASTERN STANDARD TIME